Trust backed by 50 years of experience

Accumulation of elemental technologies cultivated in tantalum capacitor manufacturing equipment

Since its establishment in 1972, Hi-Mecha has adopted the management policies of “independent management,” “company with original products,” and “the market is the world,” and has aspired to “create a company that can spread its technology to the world, even if it is small.

In addition, the concept of “Simple is the Best” has been our development philosophy since the beginning of the company, aiming to create sophisticated and stable devices.Our equipment manufacturing is based on fine welding technology and mechanical cam and link mechanisms. By applying these elemental technologies, especially through the evelopment of equipment for

tantalum capacitor production lines, we have made technological advances and developments that have earned us a high eputation in the industry. Approximately 30 billion tantalum capacitors are produced annually worldwide, 80% of which are manufactured with our equipment, and we are proud to have the largest share of the anufacturing equipment in this industry. The elemental technologies developed for tantalum capacitor manufacturing equipment are roughly as follows. We have applied this technology to manufacturing equipment for a variety of products, and our equipment is currently being used in a wide

range of fields, including aluminum electrolytic capacitors, battery devices, semiconductors, and medical equipment.

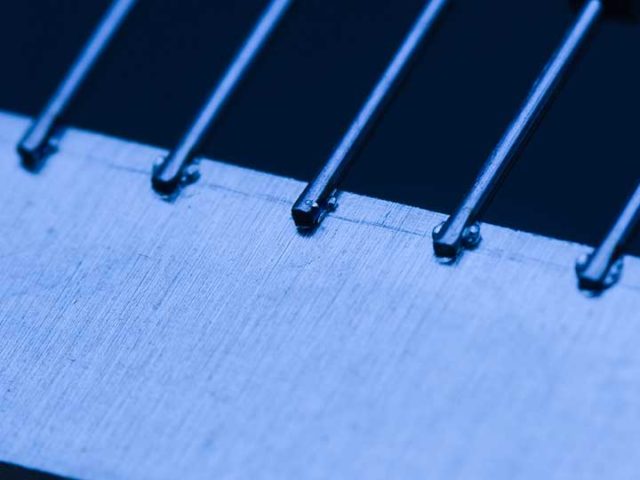

Micro Welding Technology

We have a lot of experience and know-how since our establishment. We have our own w welding power supply, and we can propose automatic welding machines, sell welding power supplies by themselves, and accept requests for welding experiments.

Precise positioning

We have a great deal of experience with contact positioning using mechanical mechanisms and non-contact positioning systems that use cameras to recognize the workpiece and perform position compensation.

High speed motion control

Based on mechanical cam and link mechanism technology, motion control devices have become more common in recent years. There has been an evolution in control devices, and we have a track record of equipment that uses high-speed multi-axis synchronous control of servo motors in milliseconds.

High precision parts machine

Our machining department has a wide range of processing machines (machining centers, wire electric discharge machines, grinding machines,

etc.) and excellent machining technicians, and can manufacture parts with processing accuracy in the micron range as needed.

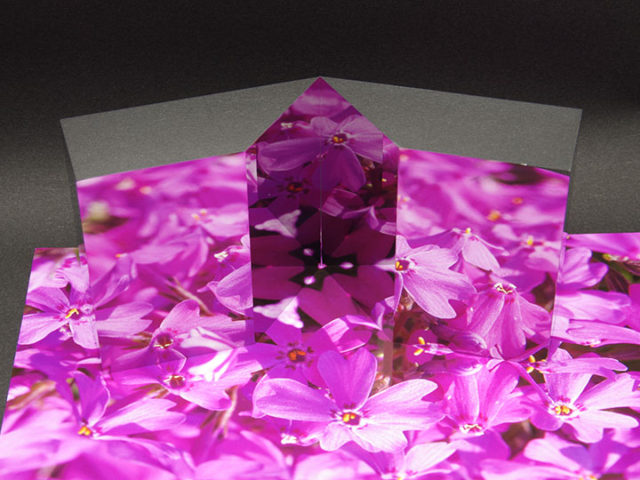

High surface accuracy finish

With the grinding machine owned by the processing department and excellent processing technicians, it is possible to finish with a surface accuracy of Ra 0.1 or less as needed.

Can be customized to meet customer needs

There is no standard specification for our equipment. All of our products are manufactured one by one to meet the specifications of our customers.

Our field of expertise is in manufacturing equipment for small electronic components (welding, assembly, inspection, etc.), but if there are any other rocesses that you would like to automate, or any issues that you are facing at your production site, please contact us.

We have a proven track record in developing and manufacturing not only capacitor manufacturing equipment, but also mass production equipment for various electronic components, semiconductors, energy devices, and other FA equipment.

Even in the case of products with no experience or track record, our engineers will come up with ideas and propose “what has never been done before and what is needed now.

Manufacturing with consideration for customer’s confidential information

1.Support for complete partitioning of equipment adjustment and start-up areas

- Thoroughly manage confidential information such as customer names, equipment names, and products by separating them by customer.

2.Support for warning displays at the entrance doors of equipment adjustment and start-up areas

- Each room’s entrance and exit is identified by a serial number for each piece of equipment.

- The work status is posted and only relevant personnel are allowed to enter.

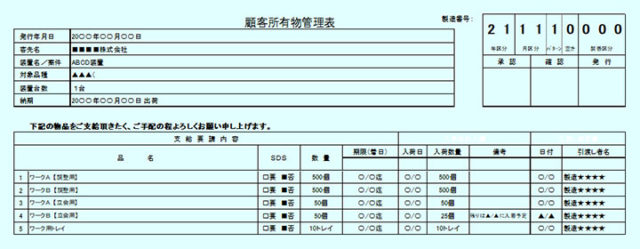

3.Management of customer supplied goods

- List and manage the materials supplied by the customer for each device.

- Supplied parts will be returned to the customer when the equipment is delivered.

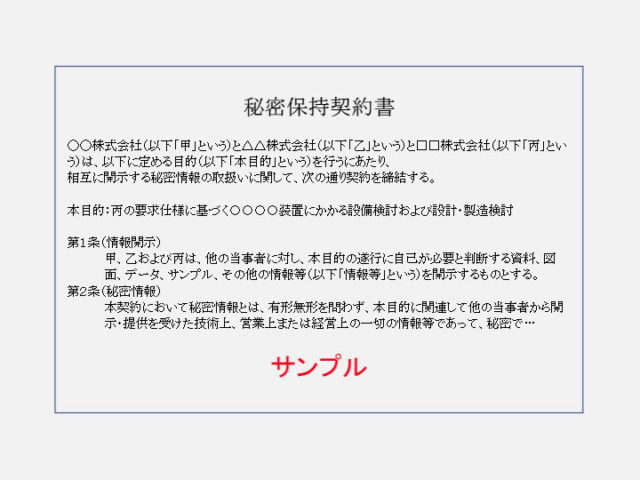

4.NDA concluded “Confidentiality Agreement with Customer”

- In order to proceed with the design study with consideration for your confidential information, we will suggest that you sign an NDA at the time of inquiry.

Support system of Hi-Mecha Co.

1.Arrangement of consumables

After the equipment is delivered to the customer, maintenance of consumables is required. Our in-house machining department is equipped with a variety of machine tools, and from here in YONEZAWA, we supply high-precision parts to various parts of the world to support our customers’ high-quality production. In China, Qingdao Machinery & Equipment Co., Ltd. acts as a contact point and provides support.

2.Periodical Inspection

A maintenance manual is provided with the equipment at the time of delivery to ensure safe and reliable use of the equipment for a long time. Daily inspections and maintenance based on the inspection report are the responsibility of the customer, but periodic inspections will be conducted once a year upon request (for a fee).

- Annual inspection (check sliding parts, grease up, check for abnormal noise and vibration, etc.)

- 2-year cycle inspection (shaft accuracy inspection)

- 3-year cycle inspection(PLC battery replacement)

3.Modification, repair, and overhaul, and relocation support

- I want to add new functions.

- I want to change or add product specifications.

- I’m having trouble with sudden problems.

- I want to consider changing the facility layout or relocating to another process.

- I would like to consider an overhaul after using it for many years.

4.remote debug

In environments where access is restricted to non-affiliated personnel of the customer, or In cases where direct response is difficult due to infectious disease countermeasures, we deliver the necessary equipment to the customer, remotely diagnose the condition of the equipment, and confirm the direction of recovery.

5.Drawing management

The equipment of Hi-Mecha Corporation has been used by our customers for a long time. We also keep drawings of our past production equipment, so we can provide our customers with genuine high-mechanical parts quickly.