By making full use of image processing for positional compensation, products of various shapes can be positioned to the micron level.

"Positioning." is a necessary function for stable operation of the equipment and for stabilizing the quality of the workpieces handled. It is obvious that the workpiece should not be damaged, and care should be taken not to change its characteristics.

Hi-Mecha Corporation mainly manufactures manufacturing equipment for electronic components, but the field covers a wide range of shapes, properties, and characteristics of the workpieces we handle, including capacitors, batteries, and semiconductors. The method of "positioning" must also be carefully examined depending on the required positioning accuracy and speed.

In particular, creating a high-precision, high-speed positioning system requires consideration of various factors such as vibration and temperature changes, as well as sufficient knowledge and experience in electricity, materials, control, and software.

Hi-Mecha Corporation has specialists in mechanical design, circuit design, control design, assembly, and processing. In addition, we have a wealth of experience and accumulated elemental technologies that we have cultivated through the manufacture of equipment.

Hi-Mecha Corporation will propose and realize the appropriate positioning function according to the target workpiece and positioning accuracy.

Here are some examples of our positioning mechanisms and systems.

Cam-driven four-jaw chuck mechanism

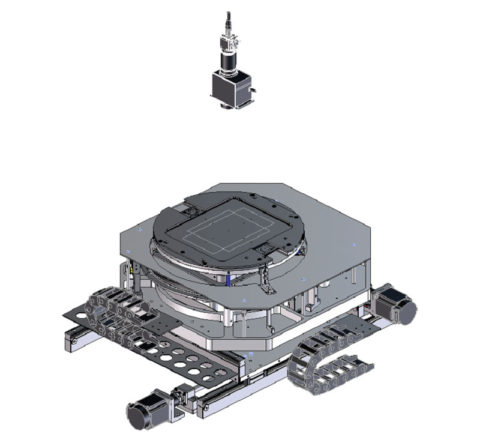

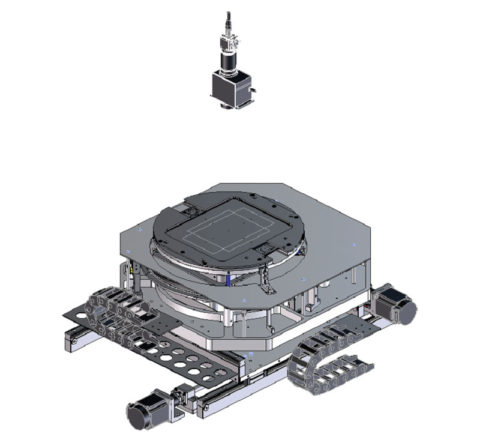

Positioning system using XYθ stage and image processing

Full closed control where the actual operating position is checked by a

linear scale

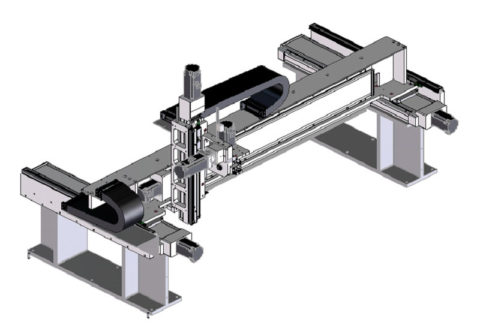

High-speed 2-arm transport and θ positioning system

A system to control the amount of weld penetration

In order to meet the needs of the industry, we are constantly striving to acquire new skills and develop new technologies. We will continue to strive for further technological advancement and deepening without being satisfied with the current situation.